Research Interests

- Material synthesis, processing, and fundamental studies with a focus on polymer derived materials, coatings, and high temperature materials

- Machine learning and computer simulation in materials processing

- Material selection, design, processing, and fundamental understanding

- Composites, hybrids, particulate materials, porous materials

- Ultrahigh surface area materials

- Additive manufacturing

Current Research

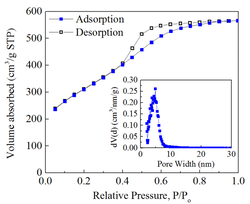

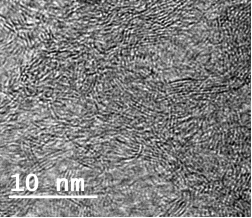

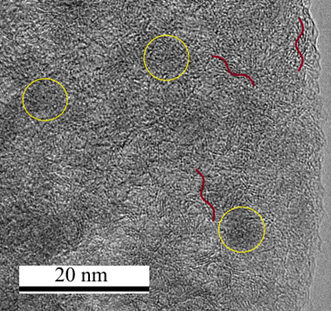

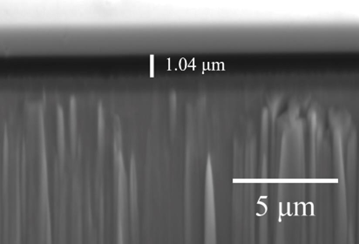

Polymer derived ceramics

Polymer derived ceramics have a wide array of promising properties such as high temperature stability, semiconductivity, and controllable microstructure and crystallization that can be finely tuned by altering the chemical composition of the starting polymer and the processing temperature and atmosphere. Current research is focusing on using silicon oxycarbide (SiOC) in environmentally stable and electrically conductive coatings, producing micro- and mesoporous SiOC ceramics with high specific surface areas, and introducing metal organics into the preceramic polymers to produce SiOC with magnetic and electrically conductive properties. We are also studying novel composite synthesis and preparing for flight experiments to the International Space Station.

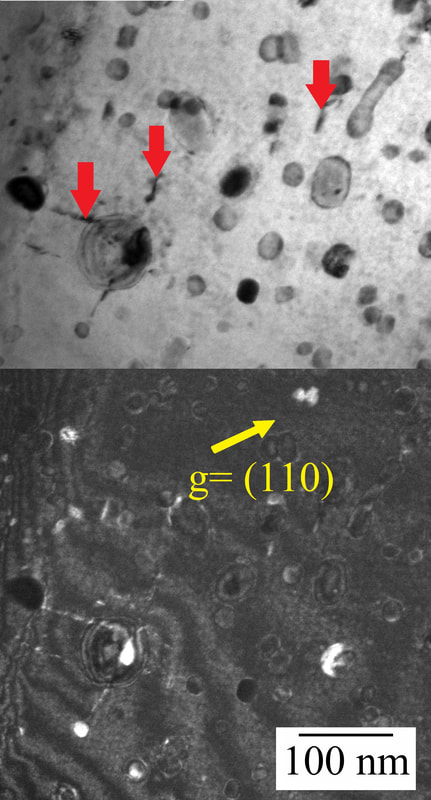

Nuclear Materials Research

Nuclear fuel design for improved irradiation resistance, easy processibility, stress tolerance, and thermal management, lab testing and ion irradiation to understand the fuel particle and bulk evolution behaviors under the simulated harsh nuclear environments, and comprehensive characterization of atomic to macroscopic structures. This will enable novel C-SiOC-SiC nuclear fuel encapsulants, improve fuel damage tolerance, understand self-stabilizing behavior under irradiation, and predict this new material system behaviors for nuclear fuel advancement.

TRISO fuels are exciting materials for energy generation. Oxidation and burn-off of the graphite fuel matrix and oxidation of the TRISO fuel SiC layer at high temperature accidental states in the presence of air and/or water vapor need to be better understood. This research will provide a comprehensive understanding of the TRISO fuel oxidation behaviors at air and/or water ingress conditions so that HTGRs can be operated with the highest safety, efficiency, and durability. Polymer Derived High Temperature Ceramic Nanocomposites

This effort focuses on fundamental understanding and atomic level tuning of multiphase carbide and boride materials by exploring species interactions during polymer to ceramic conversion as well as high temperature phase formation and evolution. The goal is to advance a new and broadly applicable high temperature nanocomposite synthesis approach through molecular level intermixing and pyrolysis. Based on fundamental studies of atomic level bonding and phase evolution using both computational thermodynamics and experimental thermodynamics, we aim to demonstrate the general applicability of this new synthesis paradigm by creating a novel class of low density materials, which should have interlocking and/or high entropy nanostructures with high thermal stability and good electrical conductivity.

MXene-Silicon Oxycarbide and Titanium Carbide-Silicon Carbide High Temperature Composites Under Microgravity and Normal Gravity Conditions

This effort will advance understanding of atomic- and nano-level species interactions under different gravitational conditions in order to explore a new class of high temperature stable and electrically conductive materials. Results from this project will open new opportunities for using microgravity to understand and create novel high temperature materials. Gravitational effects on 2D MXene deformation, stacking, and chemical interaction with silicon oxycarbide during pyrolysis is being comprehensively investigated; the phase and structural evolution of the porous systems will be correlated with pore stability and shrinkage/collapse under different gravity conditions.

New Coatings for Stainless Steel Canisters

Our interest is to develop novel coatings for nuclear fuel waste canisters in order to address nuclear waste container corrosion and failure problems, identify new and effective mitigation strategies, and safeguard nuclear waste storage, transport, and disposal, in both terrestrial and marine environments. Specifically, we develop effective corrosion-resistant polymer-derived ceramic coatings on 304/304L/304H canisters for improved resistance to pitting in chemically aggressive, chronically stressed, and highly corrosive nuclear environments; evaluate coating structural changes under different nuclear waste storage conditions and test their corrosion responses under aggressive and long-term brine conditions; and advance fundamental understanding of the coating failure mechanisms under combined stress and corrosion conditions as well as identify coating failure repair strategies, especially when exposed to pitting and stress corrosion cracking environments.

Scalability of SinteringWith the miniaturization of components and devices, it becomes necessary to examine sintering behavior differences for different micron- to nano-features and re-consider the scalability of different theories related to sintering mechanisms. By comparing the shrinkage across the varying feature sizes as well as the bulk during sintering, the degree of scalability of traditional sintering models for both one and two-step sintering will be revealed. In our study, the patterns are achieved by a soft-lithography templating technique. Our ultimate goal is to study particle clusters as small as 10 particles with an aspect ratio of ~1:1.

Gradient Cladding Composites for Nuclear Energy

This effort focuses on design and fabrication of novel gradient composites for harsh environment nuclear applications. Densification of nanostructured ferric alloy steel (NFA) and silicon carbide (SiC) composites with various compositions has been conducted by spark plasma sintering. The oxidation mechanism and corrosion resistance under water vapor condition at elevated temperature is under investigation.

|